The Best Products

Latest News

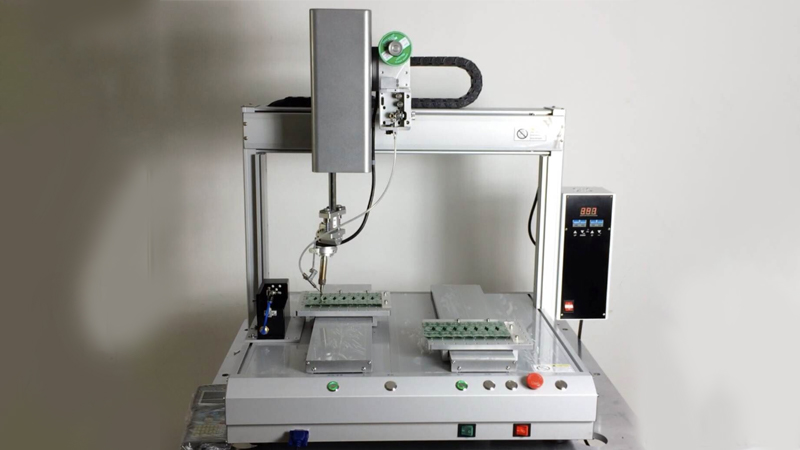

Working principle of automatic dispensing machine

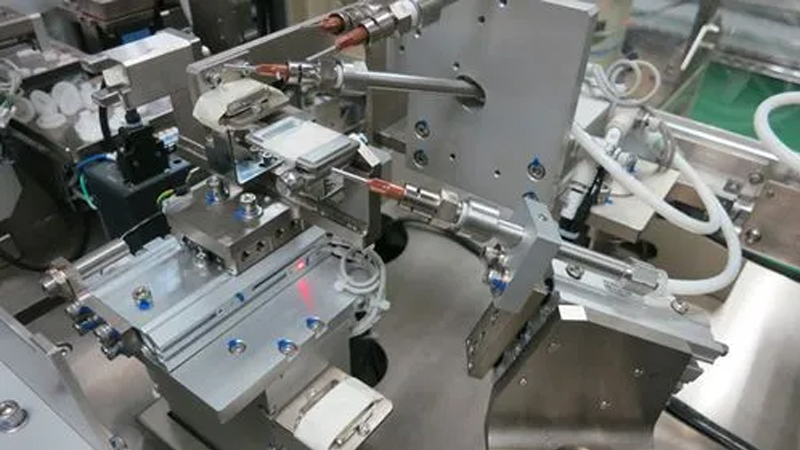

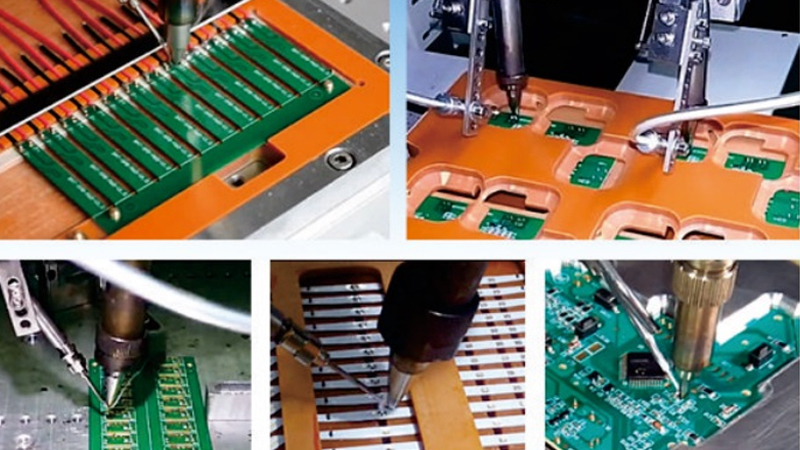

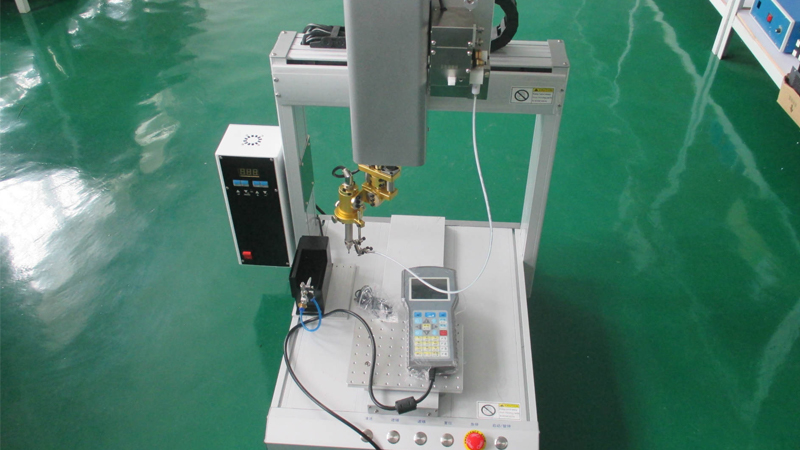

An automatic glue dispensing machine is a special type of adhesive that is pre applied to the position where the PCB board needs to be mounted to fix the mounting components. After curing, it is then subjected to peak soldering. Gluing is automatically done according to the program. 1. Tubular rotation glue control; Ordinary, digital time controller. 2. The dispensing pen head is equipped with a micro touch switch for easy operation; No air pressure required, it can work by connecting to the power supply.

Archimedean drip pump:

1. Working principle: Compressed air is fed into the rubber bottle (syringe), and the glue is pressed into the feed tube. The glue flows through a screw that rotates at a fixed time and a specific speed. The rotation of the screw creates a shear force on the adhesive, causing the adhesive to flow down the thread. The rotation of the screw continuously pressurizes the adhesive, causing it to flow out of the dispensing needle.

2. Features: It has flexibility with no fixed limit on the diameter of the adhesive dots. Adjustments can be made through software. However, when dripping large glue points, the long rotation time of the screw will reduce the overall output of the machine. In addition, the viscosity and flow characteristics of the adhesive can affect its stability.

Contactless drip pump:

1. Working principle: Compressed air is sent into the rubber bottle (syringe), and the rubber is pressed into the feed tube connected to the piston chamber. It is heated here, and the temperature is controlled to achieve consistent viscosity. Using a ball seat structure, the adhesive fills the gap left by the ball retracting from the seat. When the ball returns, the force generated by acceleration interrupts the flow of adhesive, causing it to spray out from the dispensing needle and form adhesive dots on the board.

2. Features: (1) Eliminates the adhesive tail caused by traditional methods. (2) There is no issue of wear and interference with other parts of the adhesive needle. (3) No needle nozzle damage. (4) No scrapping due to substrate bending and needle damage.

Previous: Do you know the working principle of an automatic soldering machine?

Next: No More