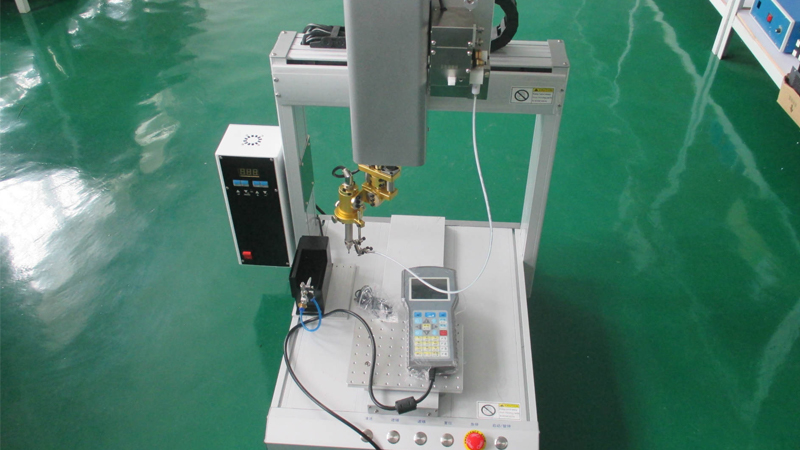

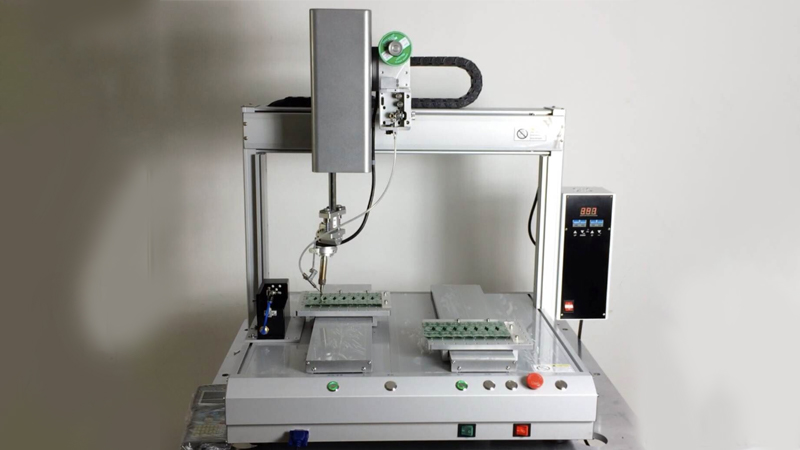

Double-platform automatic soldering machine

|

(Model) |

HX 5331R |

|

(Soldering efficiency) |

≥/H(At 2,000 points / H) |

|

(Range of each axis) |

(X axis: 300mm Y1/Y2 axis: 300mm Z axis: 100mm R axis: 360°) |

|

(Control system) |

(Microcontroller + handheld programmer) |

|

(Track) |

(Taiwan HIWIN) |

|

(Driving mode) |

(YAKOTEC closed-loop step motor + Germany TELESS synchronous belt) |

|

(Positioning accuracy) |

±0.05mm |

|

(Translational speed) |

XYZ轴(XYZ axis): 600 * 500 * 500 mm/s |

|

(Temperature control power) |

150W/200W/300W |

|

(Soldering temperature) |

0-500℃ |

|

(Program capacity) |

999+ |

|

(Programming method) |

(Straight in / teach) |

|

(Appearance size) |

720*600*850mm |

|

(Maximum load) |

10kg |

|

(Air pressure) |

3-6kpa |

|

(Power supply) |

AC220~240V 50/60HZ |

|

(Power rating) |

600W |

|

(Wire feeding way) |

(Automatic Wire feeding) |

|

(Broken Solder Wire way) |

(Pinhole-type automatic solder breaking) |

|

(Driving power) |

DC24V 3.5A/Axis |

1、 Main features (main functions):

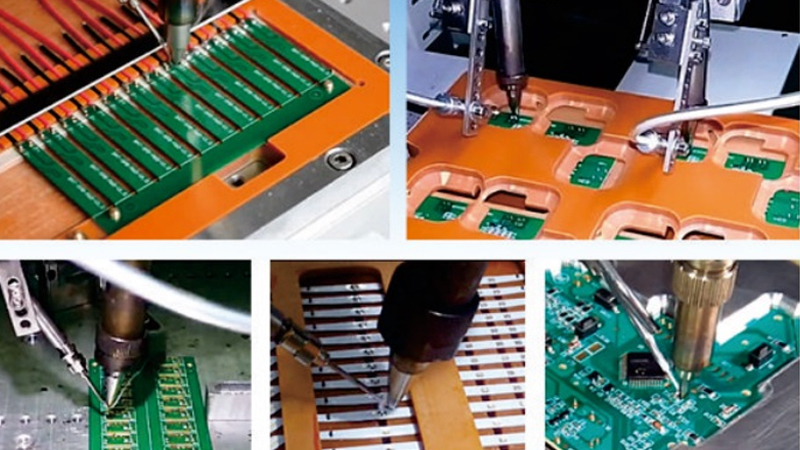

1. The X, Y, and Z axes enable the positioning of any point in three-dimensional space, while the R axis (rotation axis) can avoid components around the solder joint at any angle. Due to the fact that equipment welding is controlled by a program, there will be no manual welding or negligence around the parts

2. Adopting Weiler's original imported high-power heating core, achieving constant temperature welding, improving welding efficiency, and improving welding quality.

3. Input the set parameters is safer, faster, and more convenient. Replacing the machine manually is more effective, allowing for continuous and stable operation, ensuring the operational efficiency of the machine and operators, and requiring manual rest.

4. The automatic soldering machine controls the amount of tin in a single solder joint through program settings of tin speed and tin time. And the amount of tin at each solder joint can be individually controlled to ensure consistency between solder quality and welding quality. The solder level of each operator is uneven, which cannot guarantee the consistency of the product.

5. The automatic soldering machine is equipped with a tin cutting device, greatly reducing the frequency of tin bead production.

6. Improved the automation and standardization level of machinery, reduced the difficulty of personnel operation, enhanced the company's image in the minds of customers, and laid a solid foundation for the long-term development of the enterprise in the future.

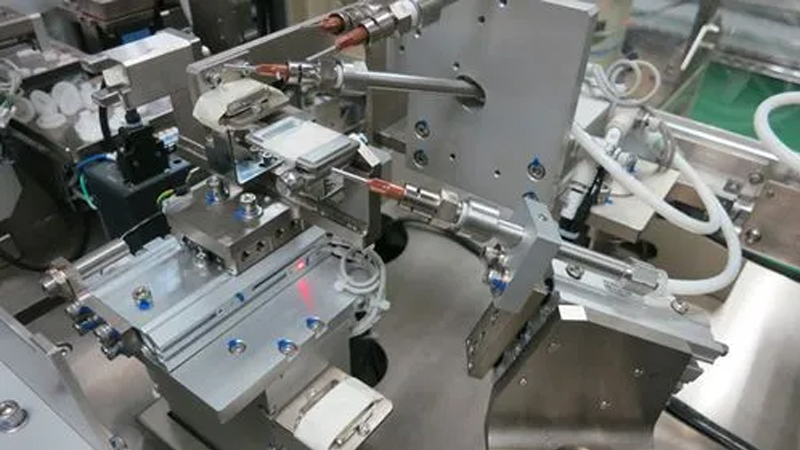

2、 Application scope:

This model is widely used in post weld welding processes in industries such as satellite communication, power supplies, chargers, motors, electronics, appliances, and automobiles.

3、 Remarks:

1. The range of motion for all axles (XYZR) can be customized according to the size of the customer's product.

2. The default motion control method is closed-loop stepper motor+belt, with options for stepper motor+screw or servo motor+screw.

3. The default appearance of the device is a metal plate shell, with an optional profile shell.

4. All accessories of the equipment are self-made or purchased externally, and do not require original factory authorization.

Previous: Single-platform automatic soldering machine

Next: No More